24/09/2019

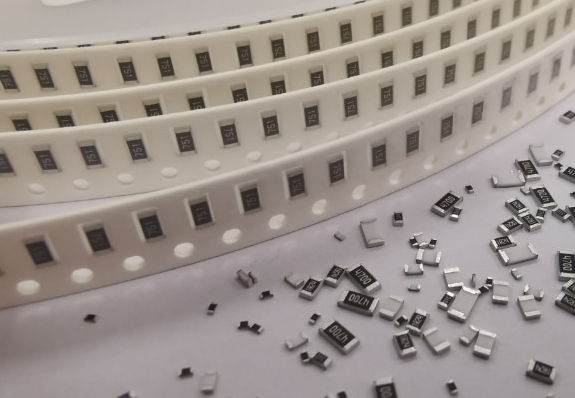

To improve the accuracy of the thick film circuit, the resistance of the chip resistor must be adjusted. Due to the inherent inaccuracy of the thick film screen printing operation, the unevenness of the substrate surface, and the non-repeatability of the sintering conditions, thick film resistors often have positive and negative errors. If the resistance value exceeds the nominal value, it cannot be corrected. After firing under printing, the resistance value is lower than about 30% of the target value, so it needs to be adjusted by laser to reach the target value.

laser Resistor adjustment system and repairing technical mechanism

Laser trimming is to position a focused beam of coherent light on a resistor under the control of a microcomputer. The laser pulse is cut and cut by a short pulse laser to vaporize and remove the film of the part to be adjusted, changing the cross-sectional area of the resistor body The resistor body lower than the target resistance value is trimmed to the allowable deviation range of the resistance value.

https://www.bingyanlaser.com/

Email:[email protected]

Whatsapp: +86 13781961057

Bing Yan Laser tiktok: https://www.tiktok.com/@bingyanlaser

Bing Yan Laser Youtube: https://www.youtube.com/@bingyanlaser