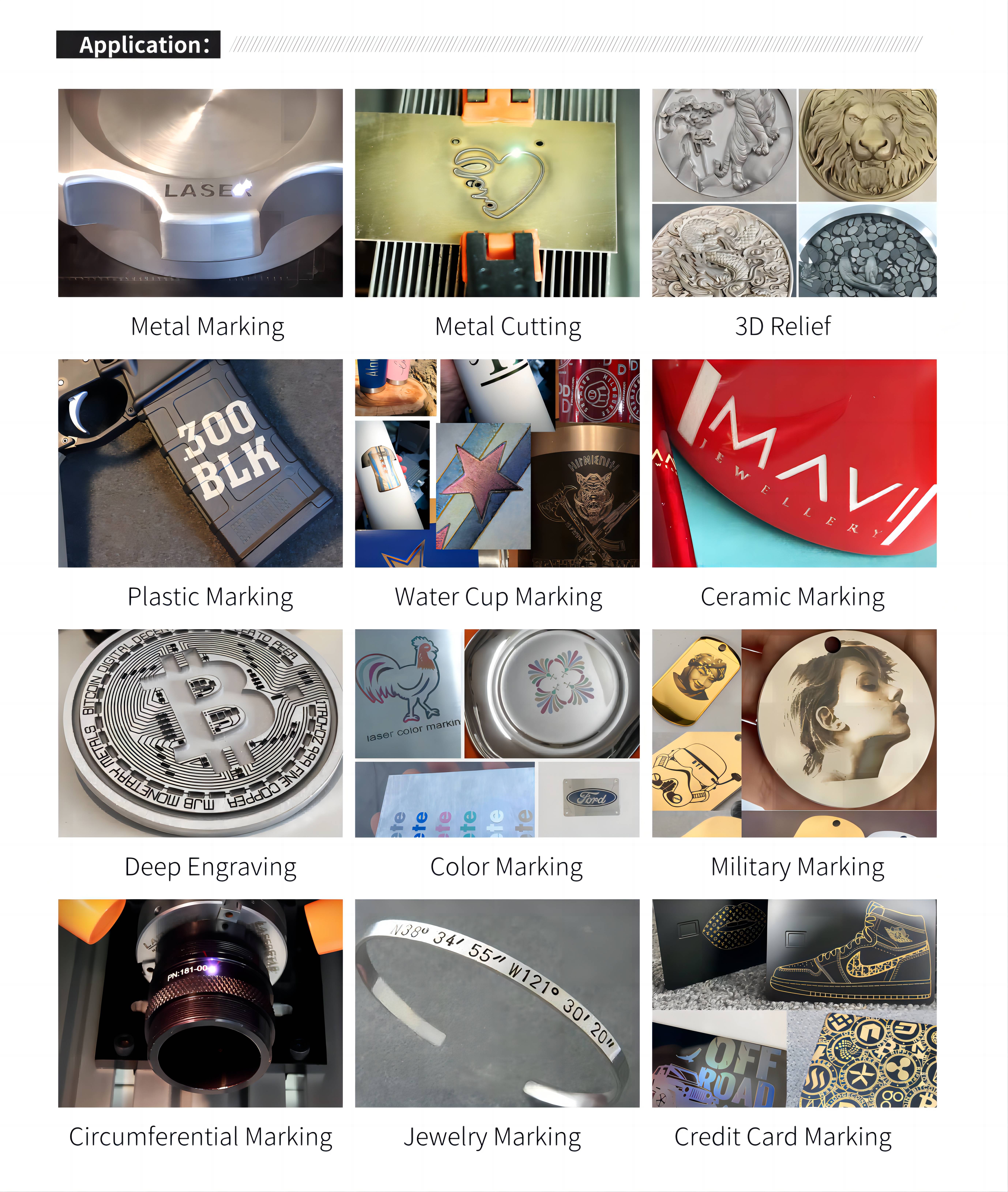

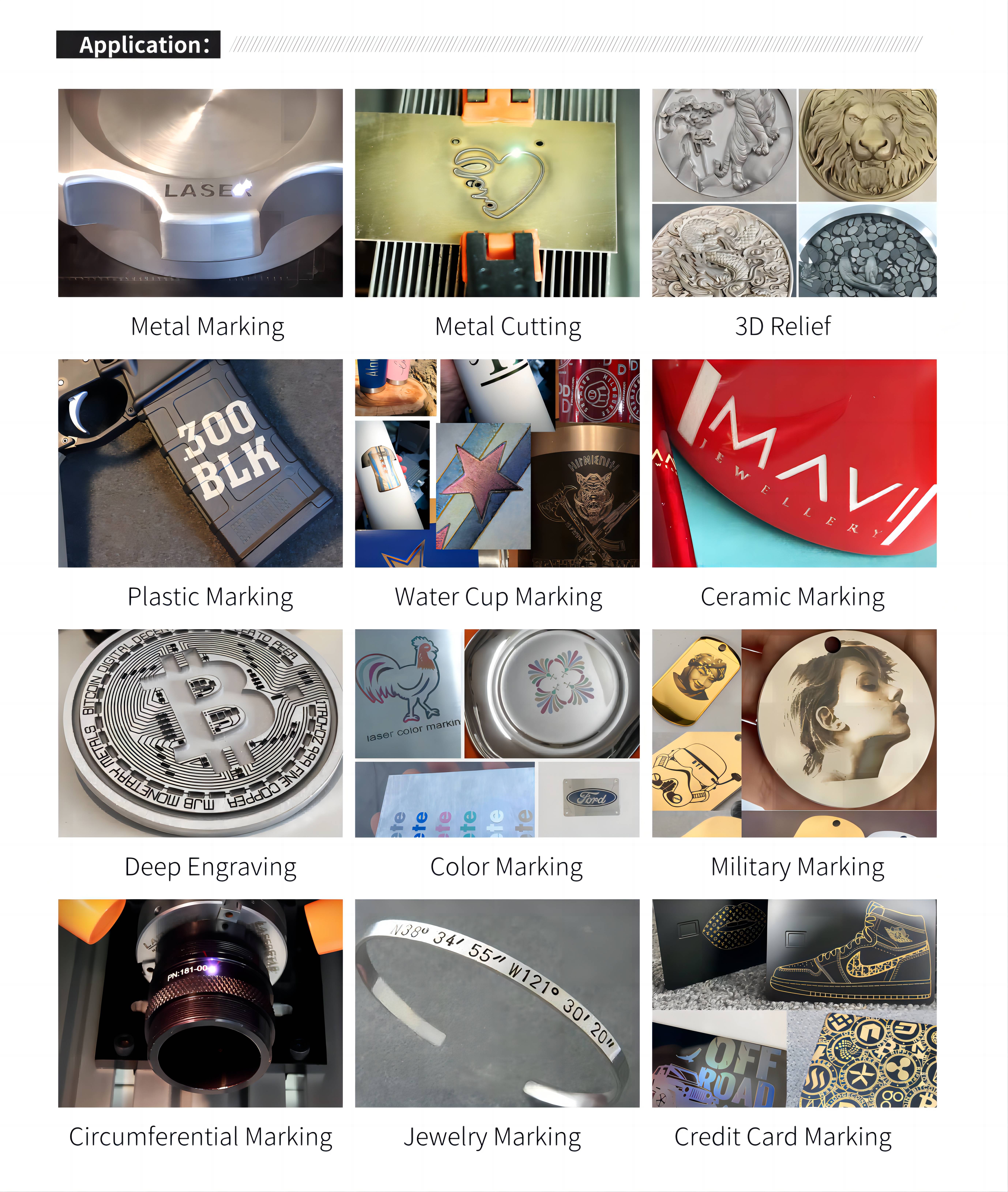

The Split Fiber Laser Marking Machine has a split design and consists of two parts: a separate laser source and a laser head connected via a flexible fiber optic cable for easy integration. The whole machine is small in size and light in weight, easy to transport .

Adopting advanced fiber laser technology, the beam quality is excellent for precise and permanent marking.

It has stable performance and fast marking speed. Supporting a variety of marking and automatic coding, it is ideal for different industries to accurately identify and trace products.

Power: 20W/ 30W / 50W/ 60W / 80W / 100W/120W/200W

Inquire Now:

Email: [email protected]

1. Maintenance-free and long service life:

Our system uses a laser diode as the pump source and is designed with a fully sealed optical path. As a result, it is extremely reliable, with an average runtime of over 100,000 hours and virtually no maintenance.

2. Fast processing speeds:

Utilizing our cutting-edge technology, processing speeds are 5-10 times faster than traditional laser marking machines. This ensures that you get your marking job done efficiently and quickly.

3. Excellent machine quality

The parts used in the machine are all famous brands—for example, JPT, Raycus laser source, ZBTK, Sino-Galvo, and so on.

4. 0 consumables

The whole machine does not need to replace any accessories within 5-10 years (under good maintenance conditions).

5. Convenient and easy to use

Integrated air cooling system, no water cooler required. No need to replace or clean lenses, etc.

| Machine Dimension | 785*645*425mm |

| Weight | 53-60Kg |

| Control Software | EZCAD/LIGHTBURN |

| power | 20w /30w /50w /80w/ 100w /120w |

| Laser Type | RAYCUS/IPG/JPT Optional |

| Marking area | 70*70mm, 110*110mm, 150*150mm, 175*175mm, 220*220mm, 300*300mm |

| Electrical Requirements | 110V-240V/50Hz-60Hz(According to local electricity supply). |

| Optional | Rotary, Cutting Fixture, Purifier |

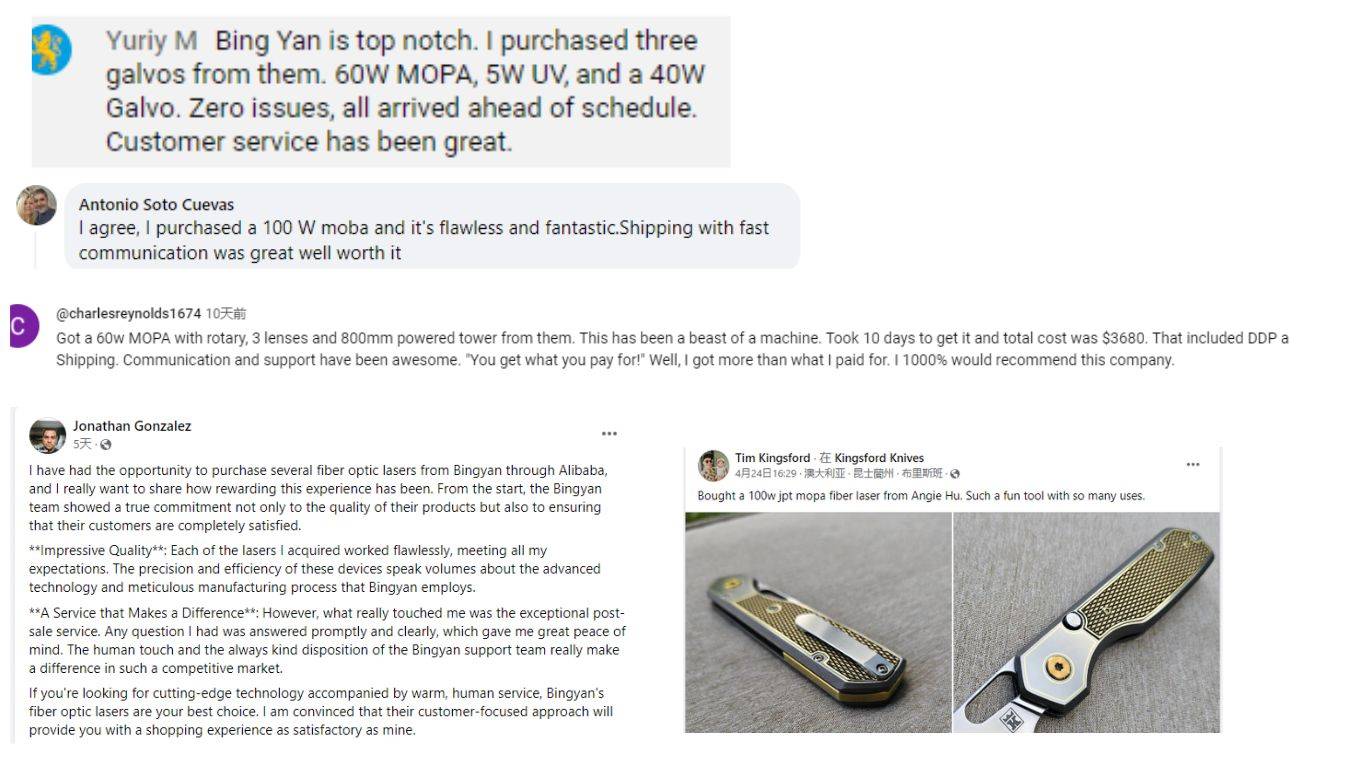

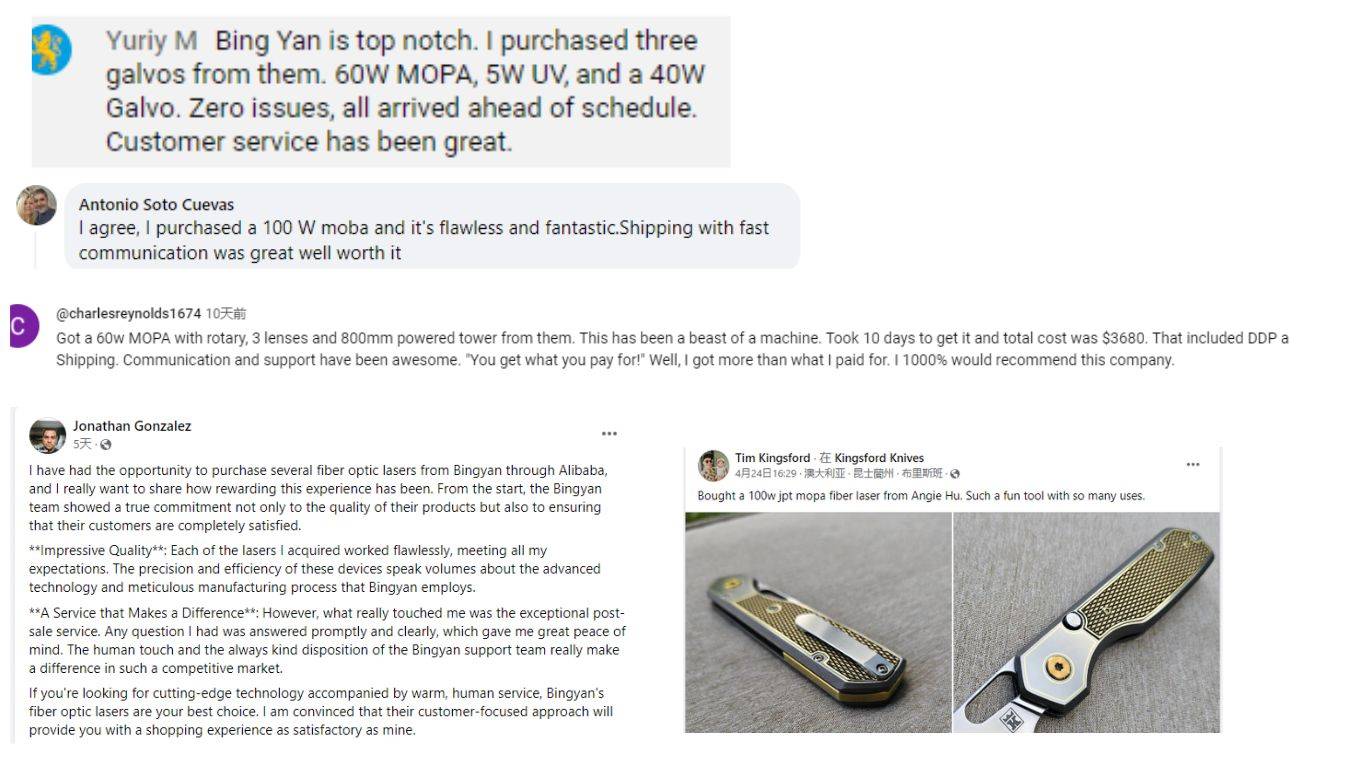

Reviews by customers:

![]()

![]()

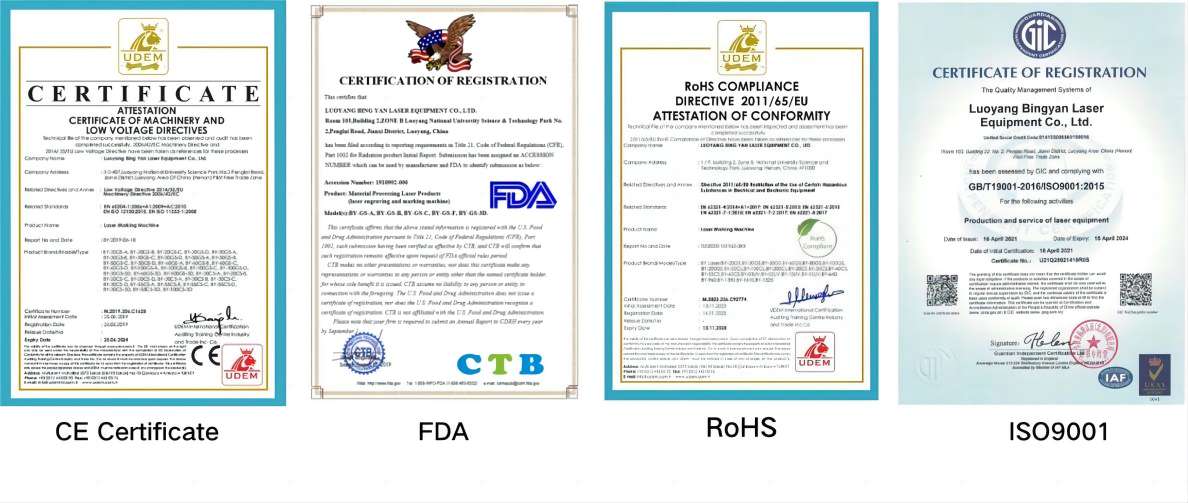

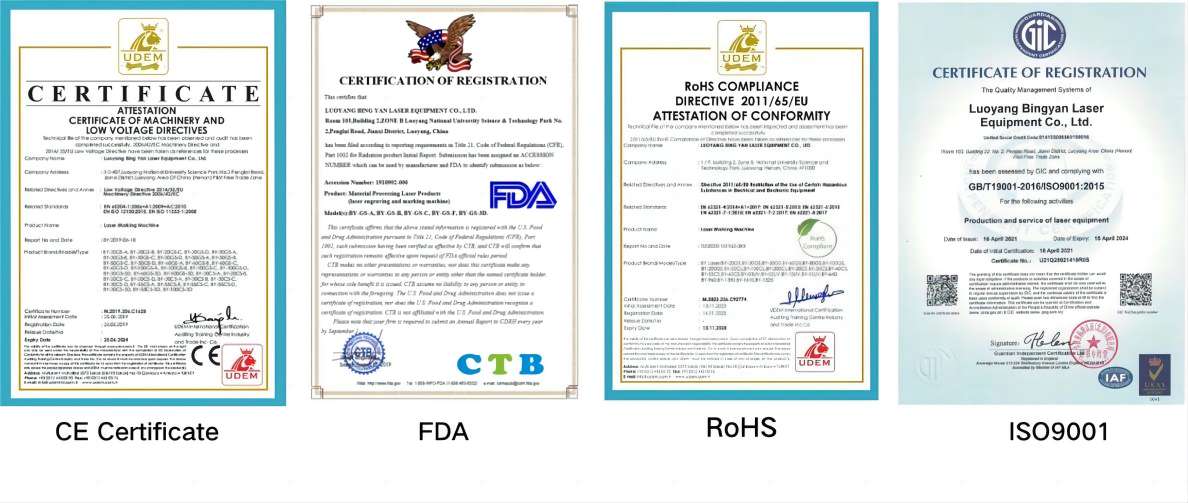

1. Why Choose Fiber Laser Marking Machine Supplier BY LASER?

BY Laser is committed to providing exceptional customer support and service. We provide comprehensive after-sales service, including technical support, training, and troubleshooting guidance. This will ensure you a smooth and satisfying experience throughout the entire process of using your laser marking equipment. We guarantee high-quality products, advanced technology, versatility, cost-effectiveness, excellent support, and customization options. These factors make BY Laser a trusted and reliable choice in the market.

2. Is laser marking permanent?

Yes, laser marking produces a mark that is permanent and resistant to abrasion, chemicals, and heat.

3. What is the difference between laser marking and laser engraving?

Laser marking is a broad term that includes processes such as engraving, etching and annealing. Laser engraving is a type of laser marking that creates a mark by removing part of the surface of a material with a laser beam.

4. Can laser marking be colored?

Yes, laser marking can produce colored marks on certain materials such as stainless steel and titanium. Black markings can be made on aluminum oxide.

![]()

![]()

Please send us your request and we will reply to you within 24 hours.