MODEL: BY-TW-A

WAVE PATTERN:Double pulse combination

PULSE WIDTH:0.2-10ms

LASER WELDING DEPTH:≤1.0 mm

THE LASER FREQUENCY:1-30Hz

SPOT ADJUSTABLE :0.2-3.0mm

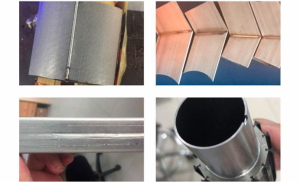

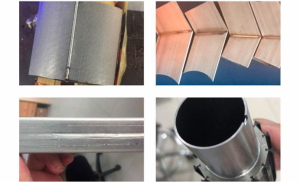

Suitable for optoelectronic communication devices, medical, electronics, batteries, polar ear, fiber coupling devices, picture tube electron guns, metal parts, mobile phone vibration motors, watch precision parts, automotive steel sheets, optical communication industry,copper parts, aluminum parts and other precision welding.

200W model: Has precise energy feedback control mode, stability <3%, excellent fiber quality after fiber optimization, suitable for precision mobile phone hardware laser welding of 1mm or less, kitchen and bathroom hardware stainless steel precision laser welding processing.

400W / 600W model: This model of laser power is large, through fiber optimization to obtain excellent beam quality, to meet the material thickness within 1.5mm, penetration within 1mm of kitchen and bathroom, home appliances, high-speed stainless steel laser welding processing.

The welding spot has a uniform energy distribution and has the spot required for welding.The control system is a professional four-axis control system ,which is specially designed for laser welding.

It has powerful PC control, easy to program, debug and maintain. It can complete automatic or semi-automatic spot welding, butt welding, lamination welding and sealing welding,the complex flat lines, arcs and any trajectory welding,with high stability, strong scalability, It is very easy to learn and to use.

Equipped with three-axis automatic workbench, large workbench, platform XY dual-axis electric module, Z-axis with power-off brake motor, it can also be equipped with rotating shaft, can realize three-dimensional laser welding for special-shaped three-dimensional products, fast speed, life Long precision.

Can be time splitting or energy splitting, suitable for different processing applications, multi-station processing applications, can be widely used in spot welding, continuous welding and flexible processing industries such as laser welding.

Small spot light spot, high power density, high melting point, high strength metal and alloy material, suitable for all kinds of complex welds, welding of various devices, flexible and convenient welding.

| Maximum laser power | 200W | 400W | 600W |

| Laser wavelength | 1064nm | ||

| Maximum single pulse energy | 20J | 50J | 80J |

| Laser frequency | 1-30Hz | ||

| Wave pattern | Double pulse combination | ||

| Laser welding depth | ≤1.0 mm | ||

| Pulse Width | 0.2-10ms | ||

| Spot adjustable range | 0.2-3.0mm | ||

| Fiber length | 5m | ||

| rated power | 8KW | 12KW | 16KW |

| Chiller cooling power | 1.5P | 3P | 5P |

| electricity demand | 380V±5V50Hz/60A | ||

| Electric translation stage travel | 200*300*500mm | ||

| Dimensions / net weight | Host size:690*1300*1070mm | 152kg | |

| 1.5P Chiller:550*550*850mm | 80kg | ||

| 3P Chiller:800*640*1200mm | 127kg | ||

| 5P Chiller:680*1130*1200mm | 186kg | ||

| Workbench:1000*700*1550mm | 220kg | ||

Please send us your request and we will reply to you within 24 hours.